RHIM Global

Home - Solutions

At RHI Magnesita, we believe in working closer to the customer to understand customer pain points and offer right solutions. Being the industry’s largest single point refractory solution provider, we offer a range of solutions to optimize your production process. Bringing in our Global expertise, we ensure that our systems increase yield, improve quality, reduce maintenance and greatly enhance safety in your operation.

We offer process measurement and optimization solutions in both the primary and secondary steelmaking process steps. Improving yield, safety and process control at the steel making stage has a huge positive impact down streams. Discover our solutions specifically aimed towards the BOF, EAF, Ladles, LF and RH areas.

Few companies in the world can offer measurement packages covering the complete continuous casting process, from the ladle to the mold. Discover our continuous casting solutions for slag detection, level measurement and ladle integrity that together or as standalone systems ensures process excellence and safety of operation.

Our patented technology gives you the power to understand and control your process. Our equipment enhances safety for your personnel while providing consistently accurate measurements and are typically used in Flash-, TSL-, SAF-, SC- and Rotary furnaces to measure bath levels on demand or continuously.

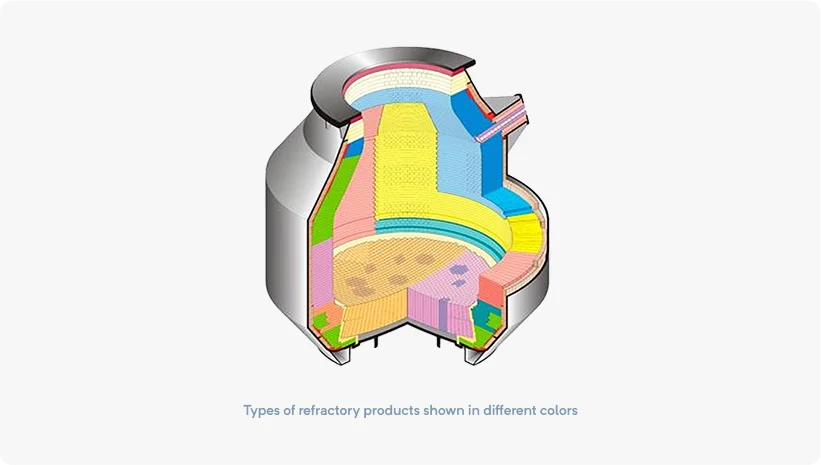

A Single basic oxygen furnace (BOF) demands different types of refractories designed according to their distinct physical and thermo-chemical properties.

One key objective for Full Line Service clients is to develop refractories that last longer and are consumed homogeneously within each equipment for each customer in each plant.

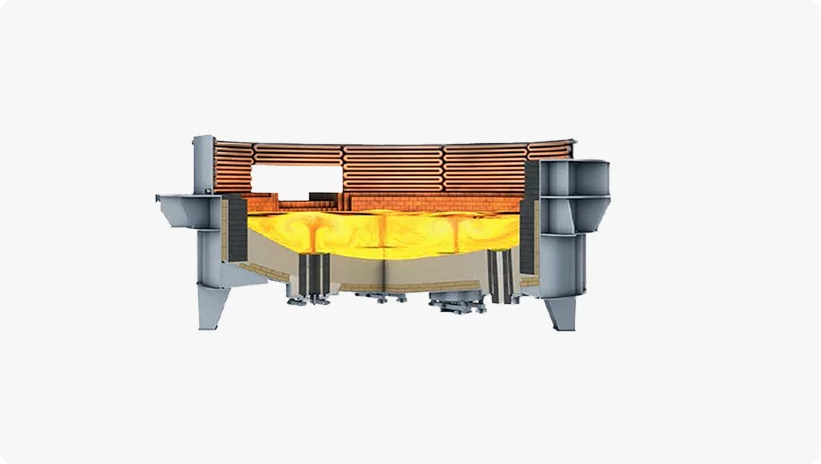

Refractory consumption on the converter walls was diagnosed as heterogeneous, potentially leading to premature disposal of other refractories within the converter. Replacing an entire wall would lead to higher downtime of the equipment and more refractory use.

| Production Facilities | Before | After |  |

|---|---|---|---|

| Charged weight (t) | 126.3 | 126.7 | +0.4 |

| Tap Weight (t) | 122.9 | 127.9 | +5.0 |

| Yield (%) | 87.9 | 92.4 | +4.5 |

| FeSi (kg) | 290 | 222 | -23% |

| Lime/Dolomite (t) | 4.45 | 4.14 | -7% |

| Power-on time (min) | 102 | 108 | +6 |

| Tap Temperature (°C) | 1.571 | 1.572 | +1 |

| Energy (kWh/t) | 543 | 526 | -17 |