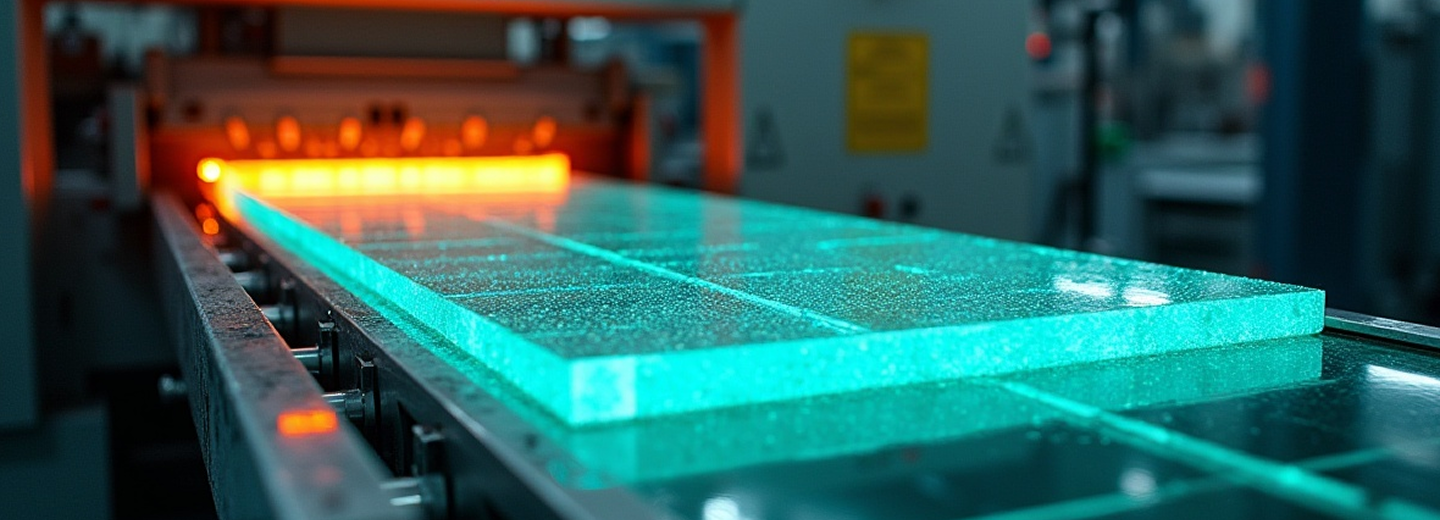

RHI Magnesita is a global supplier to the glass industry, increasing the productivity and product quality of our partners. Our experience and track record in this industry are unmatched. We offer a technologically innovative, extended high-quality portfolio in the flat glass, container glass and special glass segments.

Our product and service portfolio covers the entire range of unshaped products and ceramically bonded bricks, used in the melting process for various glass types. Our basic refractories line exhibits excellent performance in regenerators. For all of the glass industry furnaces, our silica, alumina-silica, alumina, zircon and chrome-containing high-performance refractories meet the customer requirements.

Global presence and customized services and

solutions:

Global presence and customized services and

solutions:

the key to a unique delivery and market & process-oriented package for our customers worldwide.

Extensive and sophisticated product portfolio that

enables

Extensive and sophisticated product portfolio that

enables

the delivery of optimal material solutions, providing for longer tank service lifetimes and low glass defect rates. The portfolio comprises refractory bricks and blocks as well as mixes and mortars from the following material groups:

Research and Development is in charge of the

development of

Research and Development is in charge of the

development of

new products and technical marketing, constantly monitoring refractory lining performance, improving projects, introducing new solutions, increasing performance and working for you to obtain the best price-performance ratio.

New, sophisticated services for glass furnaces like

regular

New, sophisticated services for glass furnaces like

regular

inspections help identify weak points in the glass furnace at an early stage. Also countermeasures and hot repairs such as overcoating or ceramic welding can then be initiated, extending the furnace life cycle and smooth furnace operations.

01Optimized material solutions and concepts

02Support in case of technical questions:

03Service components:

Looking for more information on our products and solutions?